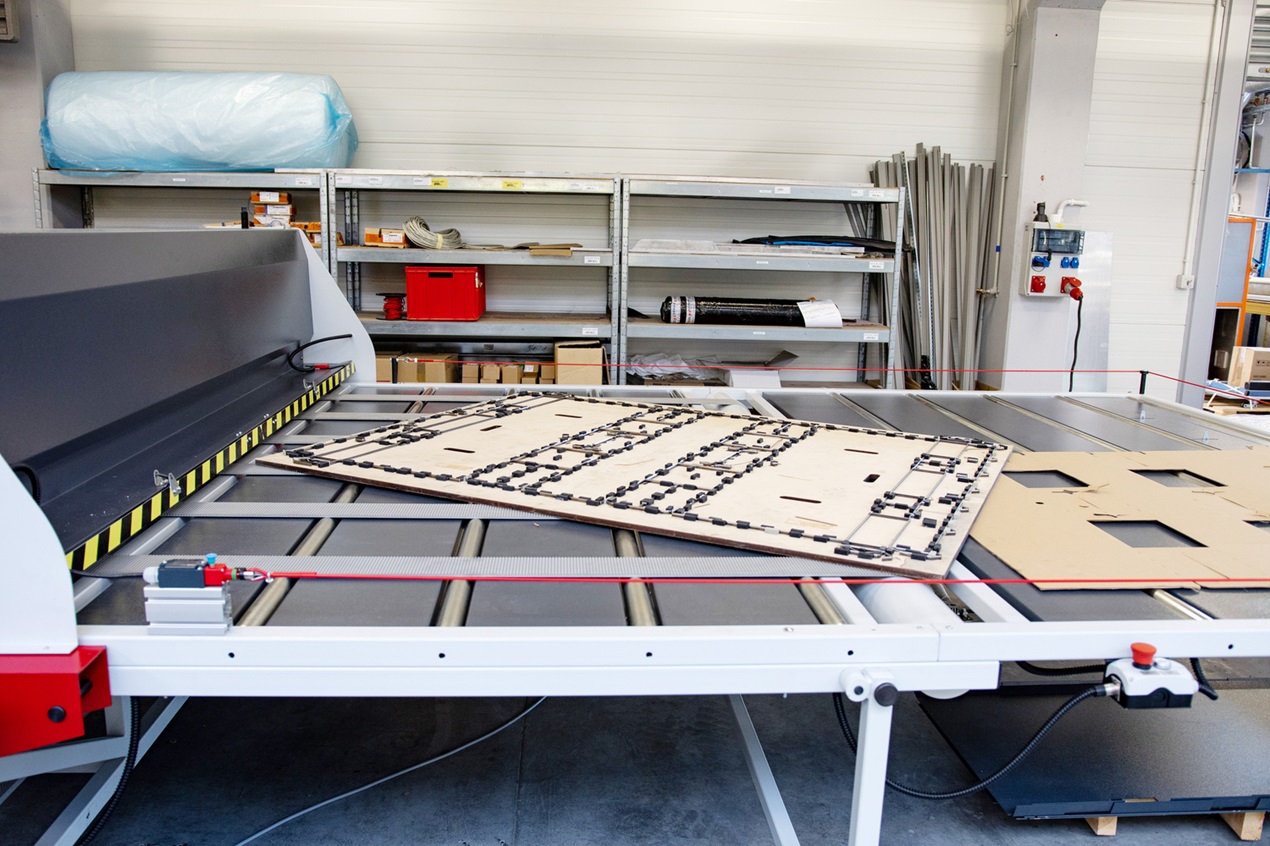

Modern die cutter machines play a key role in the packaging industry, enabling a wide variety of materials to be cut in a quick and precise way. They enable the production of packaging products such as cartons, labels or boxes that meet high aesthetic and functional standards. The precise cutting out of parts makes the finished products not only durable, but also visually attractive, which is of great importance in industries that require an appropriate presentation of goods.

Precision and repeatability in production

One of the greatest strengths of die cutter machines is their ability to provide fully repeatable cuts. Regardless of the batch size, each piece retains the same dimensions, which guarantees high production quality. These machines enable handling materials such as corrugated cardboard, paper or films, which are commonly used in the packaging industry. Precise cutting prevents deformation and the packaging is resistant to damage during transport and perfectly displays the products on the shop shelves.

Efficiency in large batch production

In the packaging industry, where fast processing of large orders is required, the die cutter machine significantly increases production efficiency. The high working speed reduces material processing time while minimising the risk of errors. Automating the process reduces material losses and operating costs, making these devices indispensable in modern production lines.

Versatility of application

Die cutter machines stand out for their versatility – they can cut both simple and complex shapes in a variety of materials, from lightweight films to multi-layered PP sheets. Such opportunities allow packaging manufacturers to create products tailored to individual customer needs. As a result, these machines are widely used not only in the packaging industry, but also in the production of advertising elements or technical components.

Advanced technology for better work

Modern die cutter machines are equipped with advanced control systems that allow operation in manual, cyclic or batch modes. The transmission belt drive delivers stability and quiet operation enhancing operator comfort. Such innovations allow machines to be used efficiently in both small and large production facilities. Zemat Technology Group offers solutions that combine precision with reliability to meet the needs of modern businesses.